Major Components of a Hydro System

Bookmark this page (Ctrl+D)

![]() View/Print PDF Version

View/Print PDF Version

Guide Navigation

Turbines and Efficiency

Turbine

The turbine is the heart of the hydro system, where water power is converted into the rotational force that drives the generator. It is arguably the most important component in the system, because its efficiency determines how much electricity is generated.

There are many different types of turbines, and proper selection requires considerable expertise. A Pelton design, for example, works best with high Head. A Crossflow design works better with low Head but high Flow. Likewise, other turbine types such as Francis, Turgo and Kaplan, each have optimum applications.

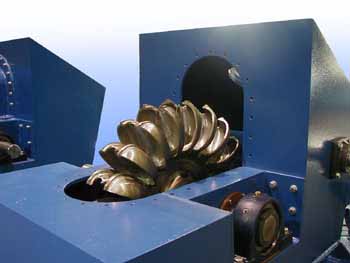

Pelton-type impulse turbine with housing cover removed.

Turbines fall into one of two major types:

- Reaction turbines run fully immersed in water, and are typically used in low-Head (pressure) systems with high Flow. Examples include Francis, Propeller and Kaplan.

- Impulse turbines operate in air, driven by one or more high-velocity jets of water. Impulse turbines are typically used with high-Head systems and use nozzles to produce the high-velocity jets. Examples include Pelton and Turgo.

A special case is the Crossflow turbine. Although technically classified as an Impulse turbine because it is not entirely immersed in water, it is used in low-Head, high-Flow systems. The water passes through a large, rectangular opening to drive the turbine blades, in contrast to the small, high-pressure jets used for Pelton and Turgo turbines.

Turbine Efficiency

Regardless of the turbine type, efficiency is in the details. Each turbine type can be designed to meet vastly different requirements, and minor differences in specifications can significantly impact power transfer efficiency.

The turbine system is designed around Net Head and Design Flow. Net Head is the pressure available to the turbine when water is flowing (more on this later), and Design Flow is the maximum amount of Flow the hydro system is designed to accommodate. These criteria not only influence which type of turbine to use, but are critical to the design of the entire turbine system.

Minor differences in specifications can significantly impact power transfer efficiency. The diameter of the runner (the rotating portion), front and back curvatures of its buckets or blades, casting materials, nozzle (if used), turbine housing, and quality of components all have a major affect on efficiency and reliability.

The turbine runs most efficiently when it turns exactly fast enough to consume all the energy of the water. In turn, the water must enter the turbine at a specific velocity (typically measured in feet or meters per second) to maximize efficiency at this RPM. This velocity is determined by Head pressure.

Optimizing Water Velocity

Since power is a combination of HEAD and FLOW, it’s easy to see how a larger orifice that moves more water (Flow) at the same velocity could generate more electricity. Conversely, as Flow drops off in the dry season, the orifice must be made smaller to maintain the same optimum velocity for efficient power transfer.

This needle nozzle provides infinitely variable adjustments to accommodate changes in Flow.

Keep in mind that turbine speed is not wholly dependent on water velocity; the turbine will turn at a constant speed because it is directly coupled to the generator, where a Governor is maintaining stable RPM by controlling the load. But as the disparity between actual and optimum water velocity grows, less of the energy from the water is transferred to the turbine. The correct orifice ensures the system is operating at its most efficient level.

Impulse turbines (such as a Pelton) are often equipped with a variety of fixed-orifice nozzles that can be used to accommodate changes in Flow. A disadvantage of a fixed nozzle is that the turbine must be shut down to make changes. A popular option is the adjustable needle nozzle, which allows on-the-fly changes with an infinite number of settings.

If you know your Head and Flow, your turbine supplier should be able to make specific recommendations for a turbine system and provide a close estimation of efficiency.