Micro-Hydro Systems Navigation

- Micro-Hydro Products - Turbine Systems

- System Options

- Design Services

- Hydropower FAQ

- Resources

- Projects

- Project Gallery

First-Time Hydropower Project?

Learn basic design

principles in the

Guide to Hydropower

Micro-Hydro System Options

Configuration Options for Systems Less than 100kW

For larger Utility/IPP systems to 20MW, please click here.

Canyon Hydro provides a broad range of turbine configurations, from bare replacement runners to complete, electronically controlled systems. Here are a few of the options you may consider for your system.

Turbine/Generator Assembly Frame

The turbine and generator must be mounted to a common frame, which is typically anchored in concrete for stable, vibration-free operation. Canyon Hydro can provide a pre-configured frame that will ensure precise alignment of your water turbine, drive system, and generator. When this option is selected, your hydro system will be shipped as modules that you can quickly assemble and align.

Runner Material

The standard manganese bronze alloy runner provides excellent life when used with clean water at heads up to 500 feet. For sites with more abrasive water conditions, we recommend our optional high-tensile, stainless steel alloy runners.

Extra Fixed Nozzles

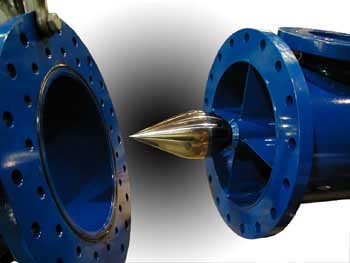

Canyon Hydro needle nozzles are machined to exact tolerances.

The majority of Canyon standard Pelton turbine systems are equipped with fixed, interchangeable nozzles. Fixed nozzles are the most cost-effective choice for sites with infrequent changes to flow. To change flow, water to the turbine is shut off, and an access plate is removed. The nozzle can then be easily changed. Canyon can provide additional nozzles machined to any size to accommodate flow variations throughout the year.

Needle Nozzle Control

If flow changes frequently, the optional needle nozzle can simplify adjustments and eliminate the need to shut down the turbine. It permits infinitely variable flow adjustment, from zero to maximum design flow, while the turbine is running. Canyon needle nozzles have stainless steel needles and beaks for extremely long life.

Governors

Governors can range from relatively simple devices to highly complex systems for larger, grid-connected hydro projects. Regardless of complexity, however, the basic function remains the same: maintain a constant RPM at the generator, and therefore a constant voltage and frequency. We will be happy to discuss your site requirements and recommend the appropriate governor type.

Most residential-grade governors work by automatically maintaining a constant load on the generator, thus ensuring a constant RPM. Typically they measure frequency many times each second, adding or subtracting electrical load as necessary to keep the frequency stable. For example, if a stovetop burner were suddenly switched off, it would remove load from the generator, which would tend to speed up. The governor would sense the rising frequency and compensate by adding more load (such as a baseboard heater) to maintain proper speed, voltage, and frequency.

Here are the two types of governors used in the majority of residential systems.

Electronic Load Governor (ELG)

The Canyon Electronic Load Governor (ELG) is highly effective for small systems up to about 12kW. Excess power is shunted to two ballast loads (such as water or space heaters), and a variable electronic control regulates the amount of power being directed to the ballast (much as a dimmer switch can regulate power to a light bulb). This design facilitates rapid and precise control, resulting in very stable voltage and frequency under changing conditions.

Load Management Governor (LMG)

The Canyon Load Management Governor (LMG) is an enhanced version of the ELG, giving you the ability to choose and prioritize how power is used.Like the ELG, it uses a variable electronic control to apply ballast loads, but it also provides the ability to manage other devices via relays.

Canyon Hydro 15 kW dual-nozzle turbine and generator system being prepared for shipment.

The Canyon LMG allows you to prioritize and control up to eight external loads, and supports hydro systems to 100kW.

Over/Under Protection Package

The over/under frequency protection package quickly shuts down your system if something goes wrong. If your generator suddenly speeds up (for example, a tree falls on your line creating an “open” condition) or slows down (such as an overload or direct short circuit), the over/under frequency protection package will remove the water from your turbine to shut the system down.

For Canyon Pelton turbines, the package consists of a Frequency Guard monitor, a turbine jet deflector system, weighted arm and electromagnet. The weighted arm is connected to the jet deflector inside the turbine, and is held in the “up” or “operating” position by the electromagnet. The electromagnet receives power from the Frequency Guard. When the frequency is abnormally high or low, the Frequency Guard cuts power to the electromagnet, allowing the weighted arm to fall. As the arm falls, it brings the jet deflector between the jet stream and the turbine runner, allowing the system to coast to a stop. Shutdown is very fast, and since the water flow doesn’t change, there are no damaging pipeline surges. The automatic shutdown is important if the system operates for periods of time with the operator is absent.

Generators

Canyon Hydro selects only high quality generators to include with our systems, ensuring efficient operation, long life, and low maintenance. In most cases, the rotating speed of the generator is 1800 rpm or slower to maximize longevity and minimize efficiency losses in the drive system. No brushes are accepted in generators used on Canyon systems, simplifying maintenance. All have automatic voltage regulators and built in exciters.

Most smaller generator units in the Americas have a standard alternating current (AC) output of 120/240 volts, at 60 hertz single phase. Other areas of the world utilize 220VAC, 50 hertz units. A variety of voltages are available in 50 or 60 hertz frequencies, both single and three phase designs.

Canyon Hydro uses generators made only by reputable manufacturers such as Marathon Electric, Kato Engineering, and Stamford (a division of Newage international).